Pet Product Material Stiffness Selector

Recommended Material

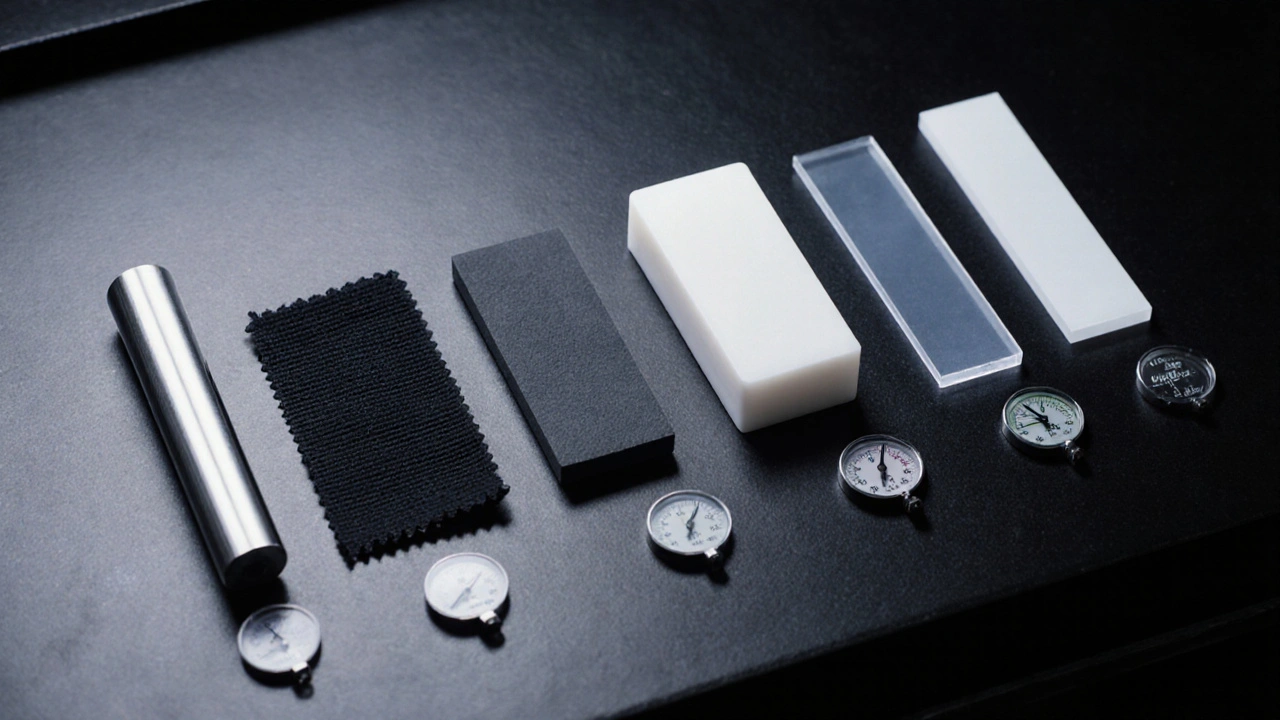

Material Stiffness Comparison

| Material | Stiffness (GPa) | Stiffness Level |

|---|---|---|

| Stainless Steel | 200-210 | Very High |

| Chew-resistant Nylon | 2.5-3.0 | Medium |

| Food-grade Silicone | 0.005-0.01 | Very Low |

| Eco-friendly Polymer | 1.2-1.8 | Low |

| ABS Plastic | 2.0-2.4 | Low |

| PVC | 2.5-3.5 | Medium |

When a dog claws a chew toy or a cat scratches a scratching post, the material’s stiffness decides if the item survives the encounter or ends up in the trash. The pet industry churns out thousands of products every year, yet many manufacturers overlook how crucial material choice is for safety, durability, and cost. This guide explains why stiffness matters, breaks down the most common pet product materials, and shows you how to pick the right one for every use case.

Quick Takeaways

- Stiffness determines a product’s resistance to deformation under a pet’s force.

- High‑stiffness materials like stainless steel are best for chew toys and feeders; low‑stiffness polymers work well for beds and carriers.

- Regulatory safety standards (e.g., ASTM F963, EU REACH) focus on material toxicity as well as mechanical performance.

- Balancing cost and durability usually means mixing a stiff core with a softer outer layer.

- Pet owners should match product type to material stiffness to avoid break‑offs and injuries.

Below, we unpack the science of stiffness and give you practical tools to make smarter material decisions.

Why Stiffness Matters in Pet Products

Stiffness, technically known as Young’s modulus, measures how much a material resists bending or stretching when a force is applied. In the pet world, a high‑stiffness product can withstand a bulldog’s bite without cracking, while a low‑stiffness item may compress under a cat’s weight, providing comfort.

Two outcomes are at stake:

- Safety: A product that shatters can send sharp fragments into a pet’s mouth, leading to injuries.

- Longevity: Durable items lower replacement cycles, saving owners money and reducing waste.

Understanding the stiffness range of each material lets designers target the right balance between rigidity and flexibility.

Common Materials and Their Stiffness Profiles

Below is a concise comparison of the most widely used materials in the pet industry. The numbers are approximate Young’s modulus values (in gigapascals, GPa) taken from manufacturer data sheets and industry standards.

| Material | Stiffness (GPa) | Typical Uses | Pros | Cons |

|---|---|---|---|---|

| Stainless steel | 200-210 | Chew toys, slow‑feed bowls, training devices | Very high durability, non‑porous, dishwasher safe | Heavy, higher cost, can be noisy |

| Chew‑resistant nylon | 2.5-3.0 | Durable toys, leashes, harnesses | Lightweight, good bite‑resistance, flexible | Can become brittle with UV exposure |

| Food‑grade silicone | 0.005-0.01 | Feeder mats, molds, grooming tools | Heat‑resistant, easy to clean, non‑toxic | Low stiffness limits structural use |

| Eco‑friendly polymer | 1.2-1.8 | Pet beds, carriers, litter boxes | Recyclable, lighter footprint, moderate stiffness | May compress over time under heavy loads |

| ABS plastic | 2.0-2.4 | Collars, feeding dispensers, toy housings | Rigid, cheap, easy to mold | Can crack under impact, not fully biodegradable |

| PVC | 2.5-3.5 | Leashes, waterproof toys, crate liners | Water‑resistant, low cost | Contains phthalates; some regions restrict use in pet products |

Notice how materials sit on a spectrum: high‑stiffness steel sits at the far right, while silicone is near the left. Your selection should align with the product’s primary function.

Matching Stiffness to Product Types

Below is a quick‑reference checklist that pairs common pet items with the ideal stiffness range. Use it as a first pass before digging into cost or aesthetics.

- Chew toys & training devices: 150-210GPa (stainless steel) or 2.5-3GPa (nylon). High stiffness prevents cracking under bite forces.

- Feeding bowls & slow‑feed devices: 150-210GPa (steel) for durability, or 0.005-0.01GPa (silicone) when flexibility is needed for easy cleaning.

- Pet beds & carriers: 1.2-2.0GPa (eco‑friendly polymer or ABS). Enough stiffness for shape retention but soft enough for comfort.

- Leashes & harnesses: 2.5-3.5GPa (nylon or PVC). Provides tensile strength without being rigid.

- Grooming tools: 0.005-0.01GPa (silicone) for gentle contact, or higher‑stiffness polymers for comb teeth.

When a product demands both rigidity and softness-think a chew toy with a plush exterior-designers often embed a stiff core within a softer shell. This hybrid approach maximizes safety and pet satisfaction.

Regulatory and Safety Considerations

Even the toughest material can become unsafe if it releases harmful chemicals. In the United States, ASTM F963 outlines safety requirements for toys, including limits on hardness (a proxy for stiffness) to prevent splintering. The EU’s REACH regulation bans certain phthalates often found in PVC, pushing manufacturers toward safer alternatives like nylon or certified silicone.

Key compliance checkpoints:

- Verify that the material is labeled “food‑grade” when it contacts a pet’s mouth.

- Check for certifications such as “BPA‑free” or “OEKO‑Tex” for textiles.

- Run a drop‑test at the product’s intended weight class to ensure it won’t shatter.

Failure to meet these standards not only risks recalls but also erodes brand trust.

Cost vs. Performance Trade‑offs

Stiffness often correlates with price. Stainless steel delivers unmatched durability but adds weight and cost-good for premium chew toys but overkill for a disposable catnip mouse. Nylon offers a sweet spot for mid‑range products: decent stiffness, lightweight, and economical.

Manufacturers can reduce cost by:

- Choosing a lower‑stiffness polymer for interior components and reinforcing only high‑stress zones.

- Utilizing recycled polymers, which typically have slightly reduced stiffness but lower material fees.

- Scaling production volume to negotiate bulk pricing, especially for steel and silicone.

For pet owners, consider the total cost of ownership. A $15 stainless steel feeder may outlast three $5 plastic bowls, ultimately saving money.

Practical Tips for Pet Owners and Manufacturers

Whether you’re buying a new toy or designing the next bestseller, keep these pointers in mind:

- Identify the pet’s force level. Large breeds generate higher bite forces; opt for high‑stiffness materials.

- Watch for wear signs. Cracks, splits, or excessive flex indicate the material’s stiffness is insufficient.

- Match texture to comfort. Combine a stiff core with a plush layer for chew toys that double as soothing blankets.

- Check label for safety certifications. Look for “food‑grade,” “BPA‑free,” and compliance symbols.

- Consider the environment. Eco‑friendly polymers reduce landfill impact, but verify they meet the required stiffness for the intended use.

Manufacturers can also run a simple “flex test” during prototyping: press the product with a calibrated force gauge (e.g., 50N for toys) and record deflection. Anything beyond 5% deformation generally signals too low a stiffness for chew‑heavy applications.

Frequently Asked Questions

What is the ideal stiffness for a chew toy?

For most dogs, a material with a Young’s modulus between 2.5GPa (nylon) and 200GPa (stainless steel) works well. The exact choice depends on the breed’s bite force and the toy’s design. High‑stiffness steel is virtually unbreakable, while nylon offers a lighter, quieter alternative.

Can low‑stiffness materials be safe for cats?

Absolutely. Cats usually apply less force than dogs, so materials like food‑grade silicone (0.005GPa) or eco‑friendly polymers (1.5GPa) provide enough rigidity for scratching posts and plush toys while remaining gentle on claws.

Are there any regulations limiting the use of PVC in pet products?

Yes. The EU’s REACH legislation restricts certain phthalates often added to PVC for flexibility. Many countries now require PVC used in pet accessories to be certified phthalate‑free. Opt for nylon or silicone when compliance is a concern.

How can I test if a product’s material is too soft for my dog?

Perform a simple bend test: apply steady pressure with your hand or a force gauge. If the item deflects more than 5% of its original shape under a load comparable to your dog’s bite force, it’s likely too soft and may break quickly.

What’s the environmental impact of stainless steel chew toys?

Stainless steel is highly recyclable and lasts for years, reducing waste compared to disposable plastic toys. The production energy is higher, but the long lifespan usually offsets the initial carbon footprint.

Choosing the right material isn’t just a design detail-it’s a safety net for pets and a cost‑saving strategy for owners. By understanding stiffness, matching it to product function, and respecting regulatory standards, you’ll end up with products that last longer, feel better, and keep tails wagging.

pet product materials that balance stiffness, safety, and sustainability are the key to happy pets and satisfied customers.

12 Comments

In contemplating the mechanical resilience of pet accessories, one observes that the Young’s modulus-a quantifier of stiffness-serves not merely as a numerical descriptor but as a philosophical bridge linking material science to animal welfare.

Indeed the safety of our companions benefits from thoughtful material selection it is essential to weigh durability against comfort simultaneously

Let us eschew layman simplifications and acknowledge that a tensile strength exceeding 150 MPa coupled with a Young’s modulus in the 200 GPa range unequivocally categorizes stainless steel as the apex material for high-bite-force taxa, thereby rendering any inferior polymer a negligent choice for large canines.

It is an egregious misstep to idolize stainless steel for every chew toy; the very rigidity that ensures longevity can engender catastrophic dental trauma in breeds whose jaw mechanics demand a more forgiving compliance.

Such a blind reverence for steel could lead to a wave of broken teeth-imagine the horror when a beloved pup gnaws on a blade‑hard object only to breaak its molars!

Oh sure, because who doesn’t love a dinner bowl that sounds like a hammer every time Fluffy decides to drink water?

The correct way to convey material properties is to state the numbers plainly and let readers interpret them.

When selecting a product, consider the diverse needs of all household pets, ensuring that size, breed, and individual temperament guide the stiffness choice so every animal feels safe and respected.

Absolutely!!! If a leash flexes more than it should, it’s a recipe for disaster!!! Choose PVC or nylon with the appropriate modulus to keep your walk under control!!!

It is our responsibility as pet owners to avoid cheap, low‑stiffness plastics that could disintigrate and cause harm-let us choose wisely.

The interplay between rigidity and flexibility mirrors the balance we strive for in our own lives, reminding us that strength without adaptability may be as perilous as fragility tempered by resilience.

Investing in a high‑stiffness feeder today means fewer replacements tomorrow; think of the long‑term savings and the uninterrupted mealtime peace for both you and your pet.